Infrared heating was the heating of choice for this incredible new build project.

This beautiful church and community centre replaced the old St.Faiths Church in Kent. The planning process for the building was long and arduous and fell by the wayside on many occasions until the Church approached Richard Hawkes of Hawkes Architecture – and so the journey began.

Infrared allows beautiful, uninterrupted design

Hawkes are great believers not only in the design advantages that hidden infrared can bring to a project, allowing more space for great impact, but also in it’s energy saving and thermal comfort properties. Energy Carbon were selected from a choice of several manufacturers and installers as the best fit for this project.

Design of the heating commenced with energy calculations to determine the predicted heat loss for the building. This is where infrared really wins out over other heating systems as there is no requirement to heat the air or ‘space’ but, instead, we heat the surfaces and occupants directly by providing an even coverage of around 30% to 60% in the ceiling. This effectively reduces the load on the building thus bringing down CAPEX and OPEX. The added benefit of surface heating is that the building is ‘charged’ with heat, a bit like a battery storing energy, which, in turn, releases to warm the air when the heating is turned off.

Bringing the Team up to speed with this new technology

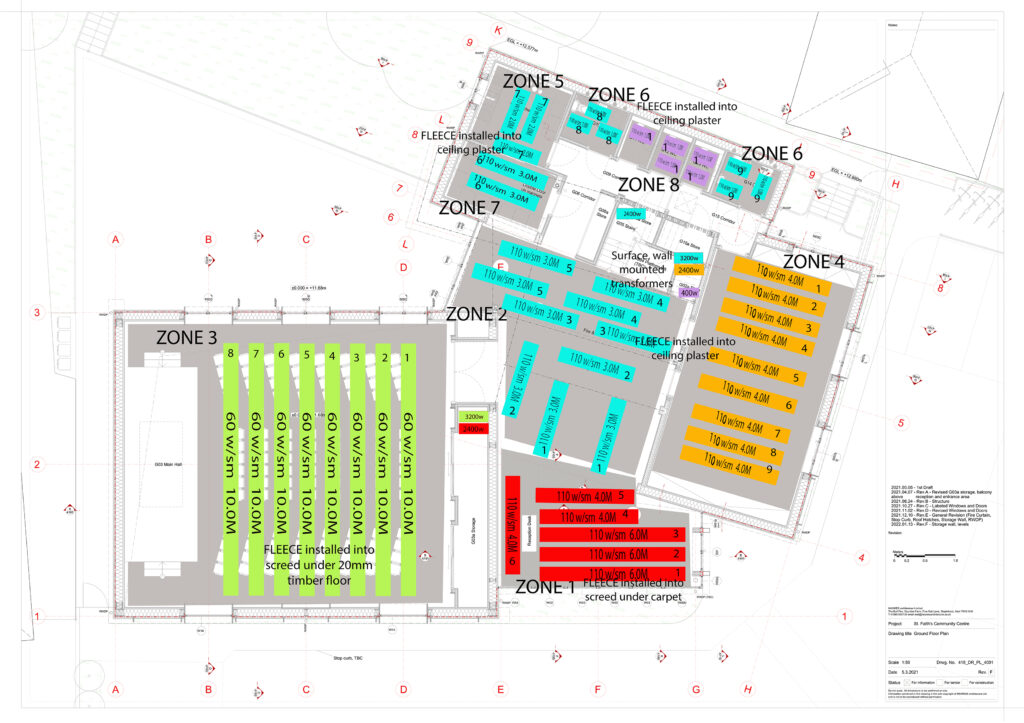

After meetings and discussions with the main contractors Harry Barnes costings were produced which led onto producing detailed layout plans showing the layout of the mats. Due to the large ceiling height of the main hall we opted to place FLEECE mats under the engineered flooring here and also in the main reception. The rest of the project benefits from our FLEECE system fitted into the ceiling.

plans showing location of infrared heating for the ground floor

The system has a heat load of just 14kw’s, not bad for a building of over 400m2! This was achieved by using our low energy, 60wm2 FLEECE product along with a series of just 5, 36v transformers feeding the 12 zones. Zoning along with efficient smart controls allow for detailed scheduling as well as preemptive heating as required, in readiness for group activities such as Toddler sessions or church meetings.

The installation commences

Electrics were carried out by the very capable team at Bexhill Electrical who, despite never having heard of the product before, carried out the install incredibly well and to a very high standard.

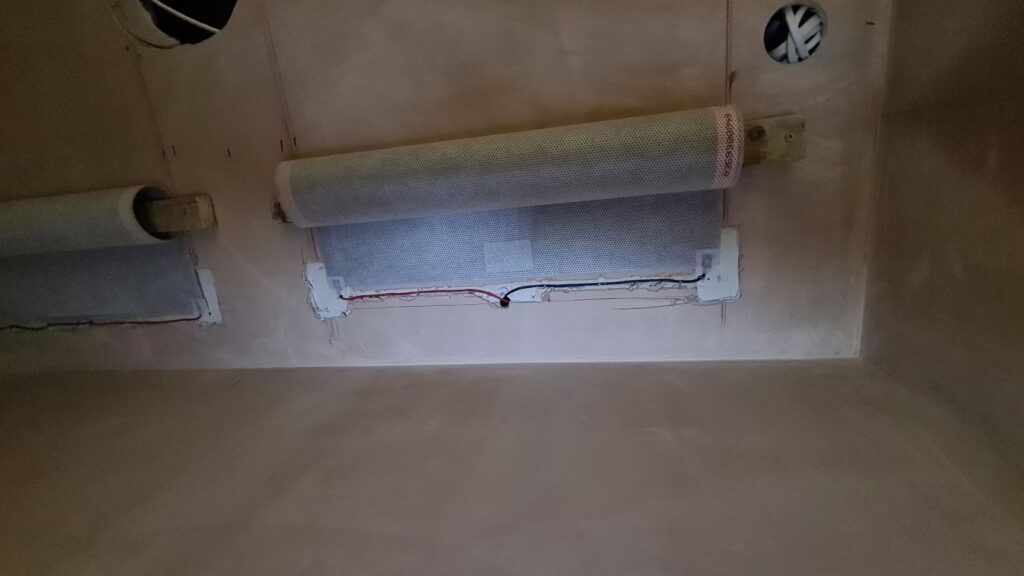

One of a series of Intelligent 37v transformers

Infrared mats ready to be plastered into the ceiling

Infrared mats ready to be plastered into the ceiling

Cables for the underfloor infrared heating

Infrared mats being plastered into the ceiling

Infrared FLEECE being installed under carpet tiles

Plastering in was as simple as pressing the FLEECE into a wet bed of Multifinish plaster before polishing off ready to decorate.

Watch the heat come to life, live, on camera

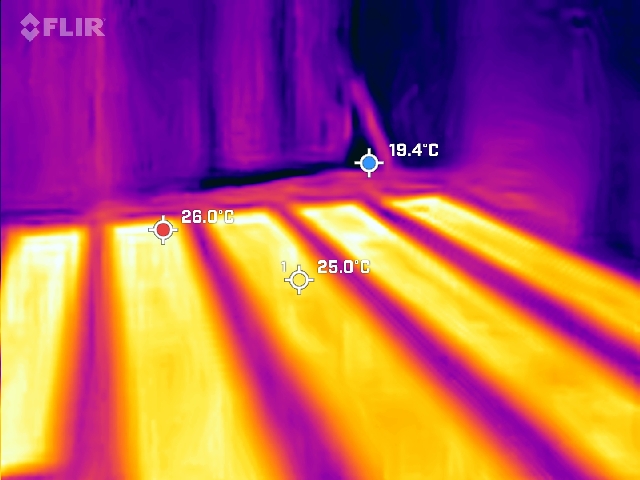

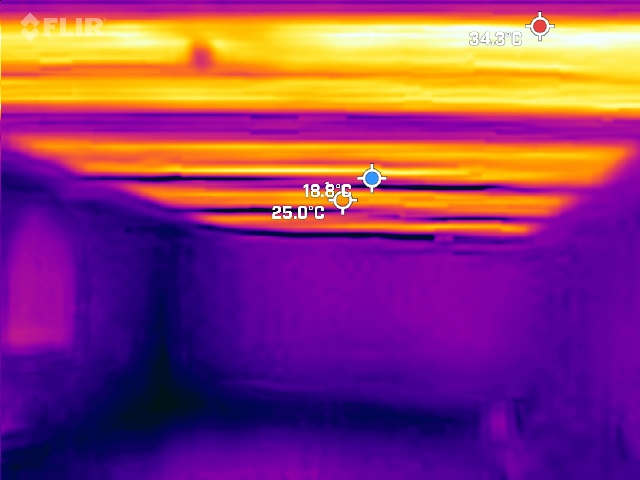

Finally, the project was fired up to test reaction time and heat output using a FLIR camera we used the FLIR One which simply attaches to a smartphone.

Infrared heating mats in the floor

Infrared heating mats in the ceiling

Infrared heating mats in the ceiling

For the full architectural design process click here

Let’s talk.

Are you interested in helping make Britain’s homes warmer, greener and more cost-effective places to be? Then speak to Energy Carbon today.

Get in touch